| References | Contact | Legal notice | Data privacy

| References | Contact | Legal notice | Data privacy

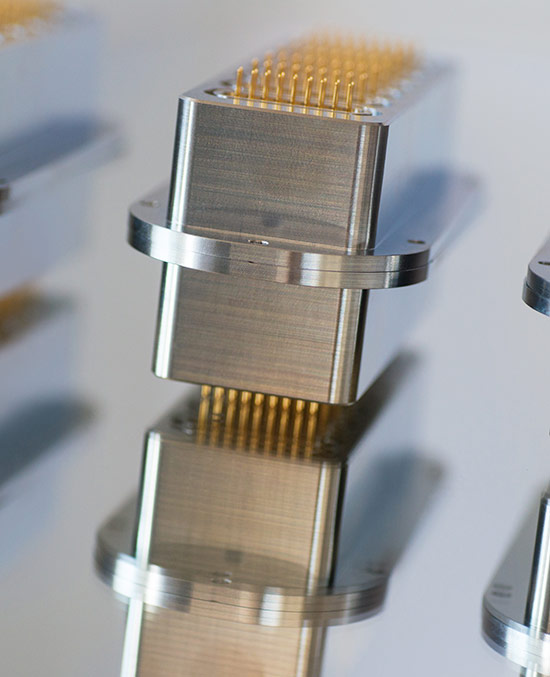

Electrical feedthroughs are components that are capable of conducting electricity through the wall of a sealed chamber. Feedthroughs consist of one or more electrical conductors that are insulated from a weldable metal housing. The dimensions, materials and design depend on the application requirements.

IPT's feedthroughs are manufactured using high-purity alumina ceramics as an insulating material and therefore, require a bonding technology which is generally called ceramic-to-metal sealing. These joints are helium tight and bakeable up to 350°C. This makes them ideal for use as instrumentation feedthroughs in HV and UHV applications as well as autoclaveable connectors for medical instruments.

| Materials Shell: Stainless Steel AISI 304 Insulation: Alumina ceramic Pins: Molybdenum or NiFe alloy |

| Bake out temperature: 350°C |

| Helium leak rate: 1*10-9 mbar*l*s-1 |

All feedthroughs are being laser welded onto flanges on request.

SMA feedthrough 50 Ohm impedance

| Dimensions pin configuration outer diameter length |

1 x Ø 0,9 mm 9,0 mm 20,0 mm |

| Ratings max. voltage max. current magnetic materials |

1150 V*1 10 A yes |

4-pin instrumentation feedthrough

| Dimensions pin configuration outer diameter length |

4 x Ø 0,7 mm 9,4 mm 25,0 mm |

| Ratings max. voltage max. current magnetic materials |

900 V*1 7 A yes |

Thermocouple feedthrough type K

| Dimensions pin configuration outer diameter length |

4 x Ø 0,7 mm 9,4 mm 25,0 mm |

| Ratings max. voltage max. current magnetic materials |

900 V*1 7 A yes |

5-pin instrumentation feedthrough

| Dimensions pin configuration outer diameter length |

5 x Ø 0,9 mm 12,0 mm 26,2 mm |

| Ratings max. voltage max. current magnetic materials |

1350 V*1 10 A (7,5 A all pins charged) yes |

SMA feedthrough 50 Ohm impedance

| Dimensions pin configuration outer diameter length |

1 x Ø 0,9 mm 9,0 mm 20,0 mm |

| Ratings max. voltage max. current magnetic materials |

1150 V*1 10 A yes |

10-pin instrumentation feedthrough

| Dimensions pin configuration outer diameter length |

10 x Ø 0,5 mm 12,0 mm 26,2 mm |

| Ratings max. voltage max. current magnetic materials |

1350 V*1 5 A (2,7 A all pins charged) yes |

12-pin instrumentation feedthrough

| Dimensions pin configuration outer diameter length |

12 x Ø 0,7 mm 15,0 mm 31,0 mm |

| Ratings max. voltage max. current magnetic materials |

1350 V*1 7 A yes |

19-pin instrumentation feedthrough

| Dimensions pin configuration outer diameter length |

19 x Ø 0,7 mm 15,0 mm 31,0 mm |

| Ratings max. voltage max. current magnetic materials |

900 V*1 7 A yes |

4-pin Power feedthrough

| Dimensions pin configuration outer diameter length |

4 x Ø 2,0 mm 18,0 mm 37,2 mm |

| Ratings max. voltage max. current magnetic materials |

1650 V*1 22 A yes |

8-pin instrumentation feedthrough

| Dimensions pin configuration outer diameter length |

8 x Ø 1,3 mm 18,0 mm 37,2 mm |

| Ratings max. voltage max. current magnetic materials |

900 V*1 7 A yes |

High voltage feedthrough

| Dimensions pin configuration outer diameter length |

1 x Ø 1,3 mm 18,0 mm 52,0 mm |

| Ratings max. voltage max. current magnetic materials |

9000 V*1 14 A yes |

We design and produce vacuum feedthroughs for use in ultra high vacuum at high temperatures.